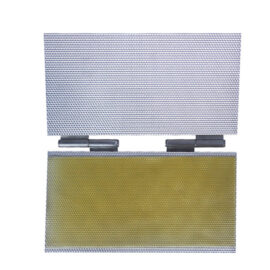

The BAIFENG wood splicer machine is a specialized pneumatic woodworking equipment designed for splicing wooden boards in beehive production. With strong compatibility for global beehive specifications, it is widely applicable to the production of Australian-standard beehives, Dadant beehives, Langstroth beehives, and other mainstream models, making it a versatile tool for beehive manufacturers and beekeeping enterprises worldwide.

1. Core Specifications

Overall Dimensions: L× W × H = 260cm × 62cm × 114.5cm

(Compact structural design ensures it occupies minimal workshop space while maintaining sufficient processing capacity.)

2. Operational Advantages

Pneumatic-Driven Design: simplifying on-site deployment, reducing energy consumption, and eliminating potential safety hazards associated with electricity use (e.g., short circuits in humid workshop environments).

Efficient Board Splicing Process: The splicing process is fast and straightforward: after applying adhesive to the board joints (if needed) and aligning the boards, the machine completes compression and fixation in a short time, significantly improving the efficiency of beehive board processing compared to manual splicing.

Waste Reduction & Material Utilization: In beehive production, many wooden boards have surface scars or internal defects that render them unsuitable for direct use as whole panels. The wood splicer machine enables the splicing of small, defect-free board segments into full-size panels that meet beehive production requirements. This not only reduces material waste but also lowers raw material costs by maximizing the utilization of available wood.

HENAN BAIFENG BEE EQUIPMENT CO.,LTD